By Gabriel Fung & Shirley Wang

Last February, when Albert Chen and his family were celebrating Lunar New Year in Taiwan, China had over 14,000 Covid-19 cases with Wuhan in lockdown and numbers climbing exponentially, while Hong Kong had just 13.

“[My dad] made the prediction that we’d have to wear masks for at least a year – which at the time I thought was crazy,” said Chen, CEO and co-founder of Masklab.

Albert’s father immediately ordered two mask machines for Hong Kong while Albert helped with digital marketing, and his brother procured materials. Time was precious: they were competing with hundreds of others attempting to enter a market with limited supply but explosive demand.

Masklab’s factory in San Po Kong produces around 100,000 masks a day, a fraction of the number needed for the city’s population of 7.5 million. They are packaged and shipped to the company’s stores across Hong Kong or to private clients overseas.

Before accessing the machine room, employees must enter a decontamination chamber and everyone wears scrubs. The floors are impeccably clean and walls are decorated with designs both new and old, displaying how the brand’s products have evolved over time.

Since last year, mask manufacturing has emerged as a sizable local industry in Hong Kong. Rhythmic pumps and presses, the spinning of metal rollers, and high-pitched noises emanating from supersonic welders fill factory spaces. At least 60 masks roll off each production line every minute.

The process involves five steps.

Firstly, the three layers that form a mask are calendered together.

Secondly, the filter media is pressed and pleated to form the folds. Then, the nose clip is fed and the material is cut.

Fourthly, the earbands are welded on and the masks sent to the steriliser.

And finally, they are taken from the machine and either collected in a box or encased in an individual plastic wrappers.

Skyrocketing demand

Hong Kong recorded its first Covid-19 case on January 23, 2020, the day Wuhan went into lockdown. Spurred by grim memories of the 2003 SARS epidemic, people flocked to stores to get masks but the shortage was acute.

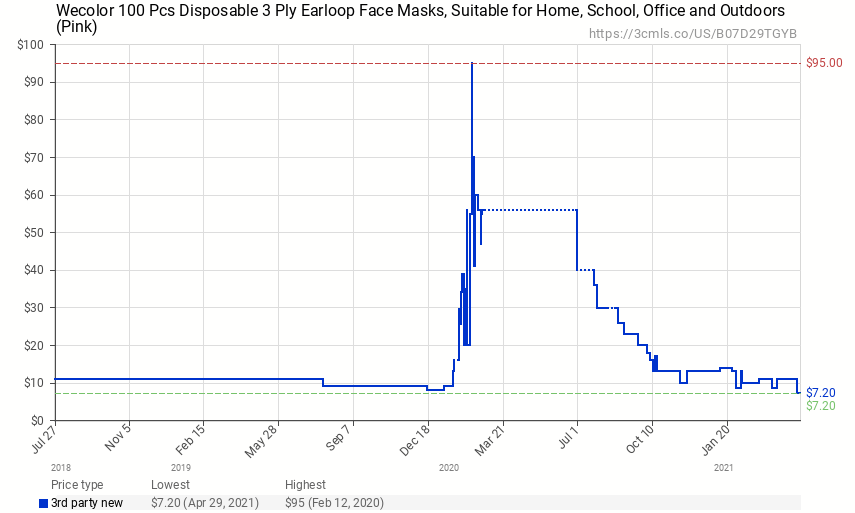

In February that year, about 20 per cent of respondents polled by HKU’s Public Opinion Programme had less than two weeks’ worth of masks, and almost 35 per cent had only enough to last a month. There was even a website that helped people calculate how many masks they would need based on family size and days of the week they had to work. Masks had also become unaffordably expensive for some.

The problem was not just skyrocketing demand and prices, but the fact that Hong Kong had no production lines of its own. The lockdown in China, meanwhile, meant crucial supply lines had been cut.

“Hong Kong had long lost its domestic industrial production and factories,” said electronics businessman Tony Lee. “And all of a sudden, people had to compete for masks.”

He and other local businesspeople saw a gap in the market and tried to jump in. “I wanted to help people, especially my clients overseas, and also earn a bit of money,” Tony added.

But many difficulties lay ahead. Prices for materials would change every three days, some countries had imposed export bans, courier services were sluggish due to cuts in transport routes and tightened customs checks, and some bank transfers would take so long that the quoted price would no longer be valid. The price of meltblown fabric, the middle layer of the mask that filters pathogens, had risen by over 30-fold. And in the end, Tony had to give in.

“Businesspeople just did not have enough experience with the process and demands of the industry,” Tony said.

He said many who tried to enter the industry were confused by the number of approval certifications needed, especially if they wanted to sell masks overseas in a situation where each country had its own requirements. The manufacturers who survived were the ones who could acquire materials in time and make sure they meet international standards.

“Being in Taiwan was the key for Masklab,” said Albert Chen. “A lot of people were trying to get their machines from China at the time and it was very difficult because China was in lockdown.”

The family was also helped by its background in the outdoor furniture business. The materials used to make cushions, of which they already had supplies, were also used in mask-making – putting the company far ahead of the starting line.

But as businesses tried to capitalise on market demand, so too did scammers. Fakes of the most crucial and scarce meltblown fabric were being sold at high prices and buyers had little time or means of checking before purchase.

Albert purchased a filter tester to do his own quality inspection. “It turned out about 80 per cent of [the suppliers] were sending us faulty filter material,” he said.

As production ballooned in the following months, people began stocking up. By May, around 29 per cent had more than two months’ supply and almost 92 per cent had enough to last at least a month. The oversupply of blue masks even forced some factories to close.

For companies to compete in an increasingly saturated market, fresh ideas were needed. In June Masklab released its first collection of multi-coloured masks; in September it opened its first pop-up store in Jordan.

Business was hectic. Masks at the factory were stacked to the roof, staff were rushing to pack boxes and there were lines outside the pop-up store. Albert even had to man the cash register for a week.

But one day, a Covid case was reported in San Pau Kong. Customers were unwilling to pick up shipments themselves, but the 500-sq-foot factory was stacked with boxes waiting to be sent. Orders were packed into one SUV and driven to the nearest S.F. Express center, with as many as seven runs the first night.

“The last two runs were past their closing time, and I remember we had to beg them to take our boxes. If we didn’t do it at the time, the next day we’d have gotten angry emails and angry Facebook messages,” Albert recalled.

Ways to survive

Currently, there are 66 retail stores operated by local mask brands across Hong Kong after many had to close down because of the competition.

The brands which survived have done so by coming up with new ideas.

Good Mask, for instance, has launched a workshop at its Central store that invites customers to print letters and patterns on their masks.

“The workshop is quite popular among our customers,” said a staff member. “Many parents like to create a special cartoon mask with their children. Some young couples also like the idea of printing each others’ names on their masks to make them special.”

Maskology sought collaborations with others. It has worked with renowned companies like Japanese toy car brand Tomica, as well as Mr. Men & Little Miss, expanding their appeal to both children and adults.

Feat.FASHION represents a potential direction for the future. Launched in April last year, the company specialises in producing reusable masks made from sustainable materials in response to the waste created by the pervasive use of single-use masks.

According to a government report in May last year, 4-6 million disposable masks are used every day, resulting in an additional 10-15 tonnes of waste added to landfills. NGO OceansAsia reported finding masses of masks even on local beaches and shorelines during a survey trip. Even so, there has not been a substantial increase in demand for reusable masks.

“In terms of differing demands, we did notice that Hong Kong locals were hesitant in adopting the regular use of reusable masks,” said Rhea from feat.FASHION.

Part of the reason is that disposable masks have been shown to offer better protection against the virus than reusable masks, particularly cloth masks.

“The general distrust of the handling of Covid-19 made people very adamant about getting the best protection there is… I believe we were helped by that,” Albert said.

Even though the pandemic has begun to wane, masks will still be necessary in the short run.

According to Dr. Benjamin Cowling – professor of the Epidemiology and Biostatistics Department at the University of Hong Kong – there are two ways out. The first is that everyone gets vaccinated. The second is to aim for herd immunity in which 75 per cent of the population has been immunised with a vaccine that has a protective rate of over 95 per cent, or an even larger percentage of the population if the protective rate is lower.

“What I’m a little bit concerned about is that there’s a third option, and that’s not getting out of the pandemic,” said Cowling, “What I mean is, in two years time we’re still wearing masks, still doing social distancing, still have on-arrival quarantine, still scared of Covid because the vaccine coverage may not be high enough. So we’re like the new North Korea. ”

“I’m serious. Because unless we can choose the other strategies, we don’t have a choice… A lot of people are reluctant to get vaccinated,” he said.

Learn from Japan

As of May 18, 787,000 people had been fully vaccinated in Hong Kong – just over 10 per cent of the population. There is a way to go before the epidemic can be declared over and Hongkongers have grown accustomed to mask-wearing whenever they are out.

“We are just used to it,” said Cowling, “I was watching a drama the other day and the thing that struck me was nobody’s wearing a mask, it was so odd that I could see [the actors’] faces!”

He thinks it is very likely that many Hong Kong people will view mask-wearing as the new normal and a social responsibility – one of the main reasons it was a practice in Japan long before the pandemic.

Japan’s usage of masks can be traced back to the Edo period (1603-1868) when people started to use mask-like devices to prevent their “unclean” breath from defiling religious rituals and festivals. When the Spanish influenza pandemic struck the country in 1918, masks became an important way to protect people.

When he started his retail business last September, Albert Chen expected his business to last until the end of 2021, and told HKFP that ultimately he looked forward to an end to face coverings. But after having celebrated Masklab’s anniversary, Albert now expects his business to go on for another year.

“I think people are more aware of the benefits of mask-wearing. There was more of a stigma to it before but I think Covid removed that stigma,” Albert said.

Tony Lee disagrees. “People have suggested before that you should wear a mask when you have a cold, but Hongkongers don’t really worry about catching one themselves if someone else has one.”

Ultimately, Albert believes masks will become a niche market, worn only for specific personal reasons like sickness. To keep business going, Masklab has begun looking into add-ons such as mask chains or aromatherapy, and will soon release its own reusable mask line.

Gabriel Fung is a journalism and politics student at HKU. He has written for The Diplomat and was previously an editor at the HKU magazine Malachite. Shirley Wang is from Beijing. She studies journalism and psychology at HKU, and previously interned at Initium Media.

Support HKFP | Policies & Ethics | Error/typo? | Contact Us | Newsletter | Transparency & Annual Report | Apps

Help safeguard press freedom & keep HKFP free for all readers by supporting our team