By Hari Kumar

The race for a vaccine against Covid-19 is entering the home stretch and reports indicate one or more companies will soon get the go-ahead to begin mass production.

Governments across the world have promised their citizens speedy access but the task facing authorities in transporting, storing and administering the doses is enormous.

Currently nearly a dozen vaccines are undergoing Phase Three trials but some will need special storage and transportation.

For example, the vaccine being developed by US drugmaker Pfizer in association with German company BioNTech has shown very promising results. But it must be stored at minus 80 degrees Celsius to retain its potency, a problem for both developed and developing countries.

US-based Moderna has also reported its vaccine has proven highly effective in a Phase Three trial and does not require storage at Arctic temperatures even though, like Pfizer, it uses the mRNA method.

Moderna says its vaccine can be kept at only at minus 20C and can survive up to 12 hours at room temperature, making it much more easier to ship.

Many of the more than 80 vaccines now being tested need storage and transport at cooler temperatures, something that major cargo handling firms are familar with. But despite a network of cold chain facilities to ensure supplies even to remote areas of the world, firms like DHL and UPS have sounded warnings about the mammoth task ahead.

Billions of vaccine vials will have to be shipped across the world on a scale never experienced before. If around 70 percent of the population needs to be inoculated to vanquish the virus,the ultimate aim would be to vaccinate five billion of the world’s people.

Production of billions of doses of a vaccine is itself a challenge that has sent manufacturers scurrying to upgrade and create new facilities.

Drug firms estimate around 16 billion doses could be made globally by 2021. Chinese authorities have said that they have the capacity to make around 650 million doses and aim to hit the one billion mark next year.

India, a major supplier of vaccines to the world, is on a similar path. The Serum Institute of India, the world’s largest vaccine maker by number of doses produced, has started setting up a US$300 million facility scheduled to produce one billion doses in a couple of years.

But mass production of a vaccine can itself pose problems. The “Cutter incident” that almost ended polio vaccination in the United States in 1955 is a stark reminder of that.

Mass production failed to replicate the chemical effect in vaccines made at smaller labs and ended with Cutter Laboratories in California producing some batches of the vaccine that actually resulted in injecting a live virus in thousands of cases.

Advances in production and technology since then could overcome such fears, and regulatory authorities have so far stuck to strict monitoring.

But once an approved vaccine moves into mass production, it brings to the fore a host of logistical problems: how to get doses from the factories to hospitals and clinics across the world.

Every connected dot on the supply chain must move at the same speed to make sure the product reaches every country in the world, starting from finding glass to make vials to supplying syringes and other equipment.

Vial manufacturers expect demand to rise by two billion as Covid vaccines are released.

The fear of shortages prompted three major glass manufacturers in Europe – Stevanato Group, Gerresheimer and Schott – to issue a joint statement in June, saying they will be able to meet the demand from vial makers.

Major syringe makers are also ramping up production. The US government has pumped in hundreds of millions of dollars to boost production after an official in May disclosed the startling figure that health authorities had only 15 million needles and syringes in their possession – just 2 per cent of what may be needed.

India, another major supplier of syringes, has also seen manufacturers ramping up their capacity. Hindustan Syringes has announced that it is aiming to make one billion syringes by 2021 – from its previous capacity of 700 million a year.

“Even if 60 percent of the world’s population is immunised, it would mean four to five billion syringes would be required,” its managing director Rajiv Nath was quoted as saying two months back.

The enormity of the task has created mind-boggling scenarios for those involved in medical logistics.

Danie Gordon, vice president of global healthcare marketing at UPS, wrote that “5.5 billion packaged vaccine doses lined up end to end would stretch nearly 240,000 miles – about 10 times around the world.”

“Our pharmaceutical cold chains at this time do not have the equipment and scale to comprehensively deliver a temperature-sensitive vaccine for the Covid-19 pandemic,” he wrote on the cargo company’s website in late July.

In a white paper published by DHL in September, the cargo handler predicted that it would take 15,000 flights over two years to provide vaccination across the globe.

“Given that temperature requirements are likely to be the main challenge, regions with a particularly warm climate and those with limited cold-chain logistics infrastructure will pose the biggest challenge in a stringent vaccine distribution scenario,” the white paper said.

Cargo giants like DHL and UPS have embarked on a massive effort to equip themselves to handle the job by expanding their facilities to hold millions of doses of the vaccine. Both companies have ramped up efforts to create cold chain farms, where millions and millions of vials can be held in a temperature-controlled environment.

DHL has established a cold storage facility in Singapore that will act as a hub for supply and storage in the region and is confident of meeting the challenges ahead.

Another problem which shippers of the vaccine will face is the absence of regular passenger flights with cargo capacity.

“The potential size of the delivery is enormous. Just providing a single dose to 7.8 billion people would fill 8,000 747 cargo aircraft. Land transport will help, especially in developed economies with local manufacturing capacity. But vaccines cannot be delivered globally without the significant use of air cargo,” the International Air Transport Association (IATA) said in September.

It said the WHO, Unicef and other vaccine suppliers had already reported severe difficulties in maintaining their planned vaccine programmes during the Covid-19 crisis, due in part to limited air connectivity.

“If borders remain closed, travel curtailed, fleets grounded and employees furloughed, the capacity to deliver life-saving vaccines will be very much compromised,” said IATA’s director general and CEO, Alexandre de Juniac.

According to IATA figures, about 25 per cent of all vaccines are rendered unusable in the shipping process, mainly due to problems after they arrive at airports, regulations at different ports and glitches during transportation to the final destination.

The shipment of a product coveted by almost everyone on the planet could also attract criminals. As vaccines will be delivered in hermetically sealed packages and not opened for inspections, the possibility of fake products arises.

Even if all these odds are overcome and millions of doses of vaccine are delivered, the whole exercise may need to be repeated in a few weeks because some of them require two shots within a specified time.

No wonder UPS termed it “an inoculation effort on a scale the human race has never before attempted.”

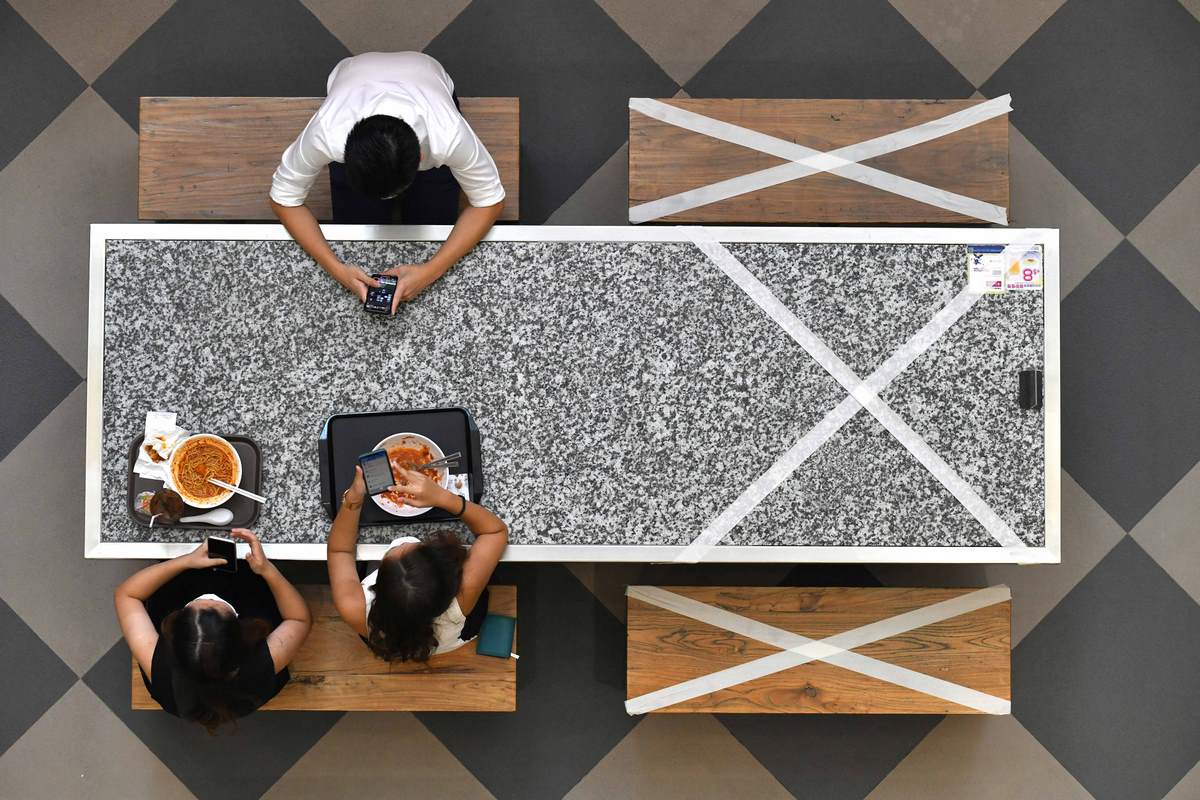

Given the time needed to mass-produce vaccines and organise transport across the world, hopes of a quick end to the pandemic seem somewhat optimistic. Facemasks and social distancing are likely to continue well into the next year.

In 2020 the world saw a race to develop a vaccine against Covid-19. The next year will see a race to deliver vaccines to billions of people – making 2021 the year of logistics.

Hari Kumar has been a Hong Kong-based journalist since 2003.

Support HKFP | Policies & Ethics | Error/typo? | Contact Us | Newsletter | Transparency & Annual Report | Apps

Help safeguard press freedom & keep HKFP free for all readers by supporting our team

LATEST FROM HKFP

HKFP has an impartial stance, transparent funding, and balanced coverage guided by an Ethics Code and Corrections Policy.

Support press freedom & help us surpass 1,000 monthly Patrons: 100% independent, governed by an ethics code & not-for-profit.